Overview of the engineering design process

The following design overview is reprinted by permission of VEX Robotics.

For more information, please visit their website at http://www.vexrobotics.com/design.

When developing a robot design, it is wise to follow an engineering design process. Essentially, the engineering design process consists of the following steps:

Identify the Need

Identify the Need

Most VEX robots are built for education or competition where a clear objective of solving a problem or scoring points is presented to the designer. With any project, you need to thoroughly understand the scope and implications of the project that must be addressed. Cost, complexity, and technology demands can quickly mire down any well- intentioned project.

Many times, thinkers, designers, and engineers do not dream up an idea on their own, but are bombarded by the problems of a customer, society, or the environment that “need” to be solved to achieve a basic “need.” Without a clear definition of this need, the engineering design process cannot begin. Much time and many careers have been wasted in the pursuit of an ill-defined need.

Define the Problem

Define the Problem

The problem is the main issue preventing the need from being fulfilled. The problem must be accurately and realistically defined in order to go about the process of solving it. If not, time and money will be wasted and the original problem may still exist with no solution.

1. Get a clear picture of the parameters of the problem or competition.

2. Make a list of the objectives and rank them in order of importance.

3. Many times a robot cannot do everything that a problem presents. It is not often that a robot can do everything well.

4. It is important to prioritize and design a machine that can do the most things and do a few things very well.

Conduct Research

Research can be an independent, lonely endeavor or a dynamic group activity. Research must be focused and incorporate new ideas and a thorough exploration of old similar ideas. Sometimes the old ideas are the best. Ever heard the saying, “Don’t reinvent the wheel?” Old ideas that failed are sometimes great research gold mines; that idea may have failed due to a lack of new technology that may exist now.

1. Explore other solutions to the same and similar problems.

2. Look carefully at the environment in which the machine has to operate.

3. Analyze the constraints of your project or competition carefully.

4. Pay particular attention to specifically mentioned dimensions and measurements.

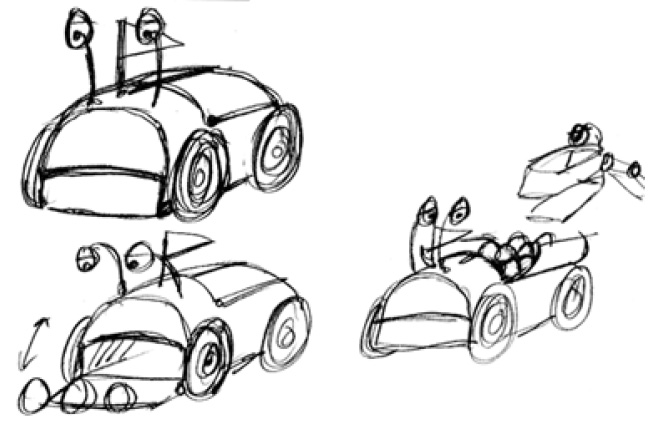

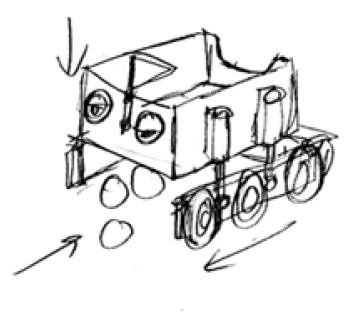

Brainstorm

Brainstorm

No ideas are bad ideas. It is important to consider all approaches to a problem. One that did not seem feasible or make sense in the beginning might be the way to go in the end. Not too many projects go through development on the first try or on the best idea at the time. The final project usually consists of a collection of ideas; some that were considered too risky, costly, or just plain crazy. Think back to famous inventors like Edison, Benjamin Franklin, the Wright Brothers, or Leonardo da Vinci. Can you imagine them using this process? How many tries did they make before they succeeded?

Solutions must be separated according to their pros and cons. This activity is better accomplished in a group setting. Brainstorming encourages a maximum amount of input from different levels of experience and different approaches to the problem. Alternative solutions can be analyzed and cataloged according to merit and possible use. After these ideas have been distilled to a manageable number, the numbers must be crunched to evaluate the probability and cost of a successful outcome, using the individual solutions. Larger factors come into play here, such as common sense and instinct. If it doesn’t feel right, don’t do it.

1. Come up with at least three design solutions and evaluate each of them.

2. Look at the number of parts that are being committed to the design. Are there enough? Can it be simplified?

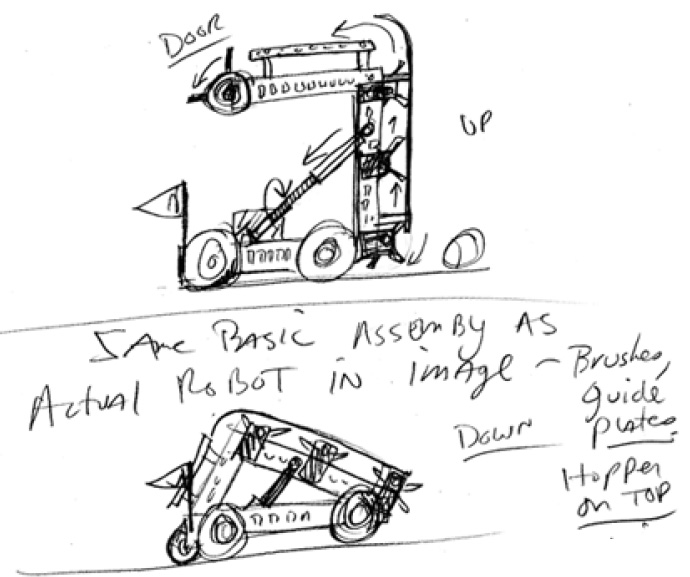

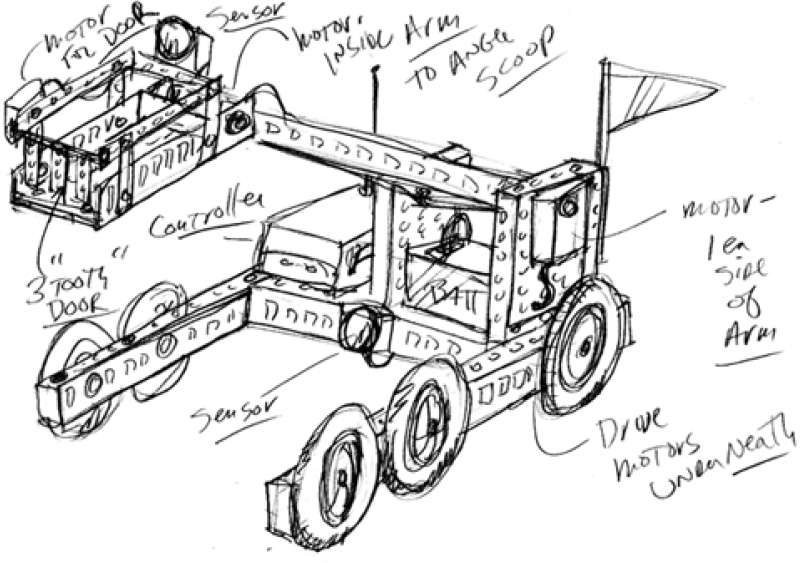

Design, Test, and Evaluate the Best Solution

Design, Test, and Evaluate the Best Solution

The design phase of a product is perhaps the most challenging of the entire process. Once the idea has been fleshed out, it is time to sit down and figure out how to make it happen. Good designers are willing to be flexible when making tough decisions and willing to make trade-offs and omissions to make the design practical and possible.

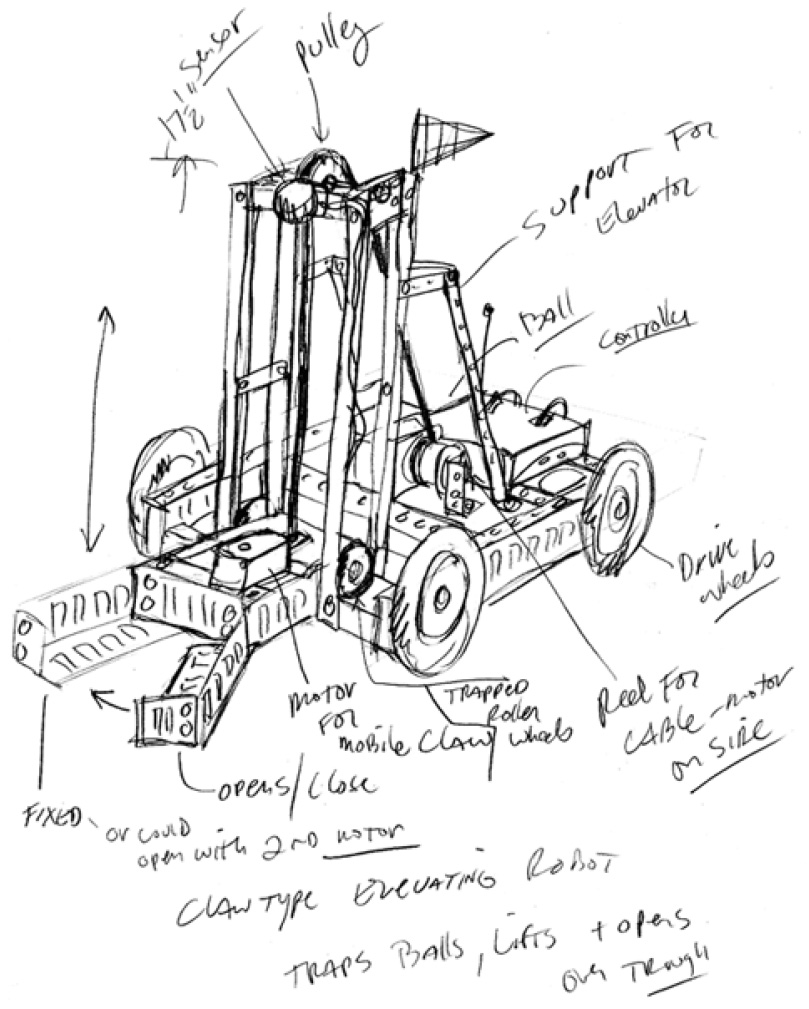

The first step is to start sketching to get the ideas on paper. Sketching and drawing by hand enables you to tap your creative side. It is important to have accurate and complete sketches in order to translate the idea into hand or CAD drawings and models. This phase also allows for virtual prototyping or testing of the product in the computer. You can find potential, and sometimes costly, flaws in a design before the real world mock-up is constructed.

Mock-ups are representations of the product to test and evaluate. This process is still valuable even though computers can accomplish the same results. The only thing they cannot do is provide a real product to evaluate. After the mock-up is evaluated, the project can go to the prototyping stage.

Build a Prototype

Build a Prototype

The best way to know if a design will work in real-world conditions is to build a prototype. The prototype is an accurate working model of the final design. The prototype is evaluated for cost, aesthetics, durability, ease of construction, and meeting the design criteria.

Refine or Redesign

If an initial design and prototype does not fully solve the problem or specifications, meet the design parameters, or stay within an acceptable cost, a designer may go “back to the drawing board” (or computer). The engineering design process has a loop to go back to the design and refine or redesign. The biggest hurdle in this refinement/redesign is money. Sometimes it is easier and less costly to settle for a slightly inferior design than spend the money to redevelop a nearly finished product.

Build

The build process is a lengthy complex process. The build process must take into consideration materials, processes, construction limitations, and cost. Companies make substantial investments in factories and the infrastructure to build their designs so the more efficiently a design has been handled, the better off the build will be. Once the build process has begun, the company can begin to hopefully make a return on its investments in the entire design process by marketing and selling the product.

Hot diggity dang it was like totally radical.

really long but cool