How to Make a Fast Pinewood Derby Car

Packs nationwide are gearing up for their annual Pinewood Derby. There are a variety of ways to make your Pinewood Derby car go faster. Explore the following tips to optimize your car’s performance and gain a competitive edge in an upcoming race.

BASIC GUIDELINES FOR PINEWOOD DERBY CAR DESIGN

The possibilities are endless when it comes to picking a shape for your Pinewood Derby car. Before you begin, consider the following general guidelines:

Avoid Pointed Noses: A pointed nose will make it difficult for your Pinewood Derby car to rest on the pin at the starting gate. It may also cause your Pinewood Derby car to get bumped around when the pin drops, and it can create problems for electronic timing systems at the finish line.

Weight Distribution: Leave ample wood in the rear of the Pinewood Derby car so you can place additional weight there. Concentrate the majority of the weight in the rear for optimal performance.

Maximum Weight: Aim for the maximum allowable weight, typically limited to 5 ounces in most races. If your car falls short of this weight, strategically add coins or other weights to meet the requirement.

Clarity in Orientation: Clearly distinguish the front and back of your Pinewood Derby car. In many races, the race officials — not you — will actually place each Pinewood Derby car on the track. Sometimes the officials put the Pinewood Derby car on the track backward because they can’t tell which end is which.

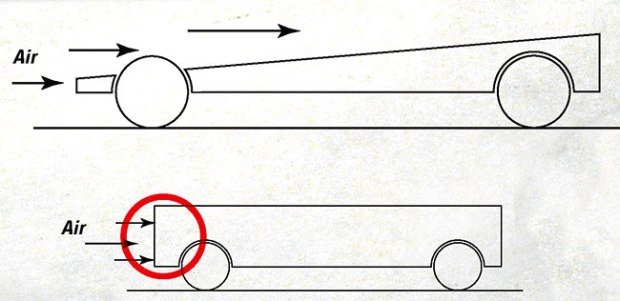

Aerodynamic Design: Select a design that facilitates smooth airflow over and around the Pinewood Derby car body. Pinewood Derby cars with aerodynamic profiles go faster.

See photo galleries of hundreds of Pinewood Derby car designs.

10 STEPS FOR DESIGNING AND BUILDING YOUR PINEWOOD DERBY CAR

You don’t have to strive for the fastest Pinewood Derby car to have fun competing in your Pinewood Derby. But if you and a helpful adult are willing to put in the extra time and effort, these tips are for you.

1. Bake the Block: Start your Pinewood Derby car project by baking the wood block at 250 degrees for two hours. This removes moisture and lightens the block, allowing you to place more weight at the rear of the car where you actually want it.

2. Crafting the Design: Outline your Pinewood Derby car on paper, cut it out, and affix it to the wood block.

Remember, a rectangular car is not an aerodynamic design. The most basic aerodynamic design is a simple wedge. If you don’t have time to design a complex car, a wedge will work just fine.

Download a Pinewood Derby car template PDF to help you create your design.

3. Rough Cut the Design: Use a coping saw or enlist the help of a responsible adult with a power tool to cut out the rough shape of your Pinewood Derby car.

4. Shape Your Car: Smooth edges and shape your car using sandpaper. An adult can assist with a rotary tool or other shaping tools.

5. Sand and Paint Creatively: Reduce friction by smoothing the car’s surface and paint an awesome design to make it look great.

How to paint your Pinewood Derby car to give it a shiny finish.

6. Axles and Wheels Alignment: Make sure they are aligned perfectly straight. You can test the alignment of your axles by pushing your car across a smooth floor or table. It should roll smoothly in a straight line.

— Consider a Three-Wheeler: Raise one wheel about 1/16 inch higher so it never actually touches the track. Less friction = more speed. Rules vary from pack to pack, so make sure to check your pack’s Pinewood Derby rules to make sure three wheelers are allowed in your race.

— Extend the Wheelbase: Maximize the distance between front and rear wheels. Again, make sure this is allowed in your race.

Learn about polishing Pinewood Derby axles and wheels to reduce friction.

7. Secure Axles with Glue: Glue the axles firmly in their holes to ensure that they stay perfectly placed, but make sure you don’t get glue on your wheels.

8. Strategic Weight Addition: Remember to make your Pinewood Derby car as heavy as the rules allow. In general, it’s best to place weight to the rear of your car because a heavier rear increases speed.

Learn scientific Pinewood Derby speed tips from a former NASA engineer.

9. Use Graphite: Add graphite or another dry lubricant to reduce friction. The less friction between the body and wheel, the better.

10. Have fun! And finally, remember the most important rule of a Pinewood Derby is that it’s supposed to be fun. While you should always strive to do your best, don’t get caught up in winning or having the fastest car. Just enjoy the ride.

Adapted from the book “Pinewood Derby Speed Secrets,” DK Publishing, $12.95 softcover.

This actully works

this is my last year doing pine wood derby so this better work

ran my car was raceing i all was lost but next year i will win the race

If I do a golf ball design and drill holes in it will it slow it down, do I just paint the holes.

my car got radard to see how fast it was and it got 48.9 mph

what is the secret to making long distance derby cars?

I did a derby with my 4 kids for the first time. They didn’t have the fastest cars but they were made by THEM. The only thing my hubby did was cut them out. The kids designed, sanded, painted and helped place the wheels. I was proud of them for working so hard. With these tips and seeing different cars at the race, next time they might do better. We had a lot of fun!

still don’t get it.

it is very cool though it looks hard to make

my son got 2nd place, and the trick was to create a wedge with a block of wood at the back, and LOTS of graphite on the wheels. an older scout beat him once, but other than that, he was undefeated.

I got 6th place.glue the axel.

Great tips guy all across the board ! Where is the best place to drill hole into the bottom of car ? And where is the best place to set any additional weights ? Thx

If you drill holes in the bottom to reduce weight, will it slow the car down if they are not filled?

drilling holes will not slow the car down. but if u do want to fill in hole or fix a spot without adding weight I have found that dry wall plaster works great. easy to use sandable and comes in small tubes in hardware dept $2.50? And u can use it to cover up small dents scratches and nail holes in your wall befor u paint. so with kids being kids it wont go to waste.

My boys need to remove more weight, the tip book mentions drilling holes underneath near the front, but does not mention filling them with anything. Will the car go slower if there are holes in the bottom? We need to remove front weight to add it to the back.

Lots of great ideas out there. If your going to make modifications to the car make sure your son is the one doing it. My 7 and 10 year old both did all the work on there cars to include removing bers and polishing the axels. Its not dificult. They learned alot and had fun doing it. Show them how on one and let them do the others. They enjoyed there first place den wins and 2nd and 3rd wins in the overals.

Eh, aerodynamics don’t matter. Graphite and the axles are what matter.

i agree only the axles and wheels matter

a dad in my pack made a smoken fast block

I agree. But if the race comes down to 1-1000 of a second it might help?

I recommend to cut a notch under the front of the car

i would recomend to cut a a slot under the car in front so when the pin go down the car has been movin the whole time

Some people are whiners.our rules are what comes in the box.do check to make sure your pack has no additional rules.then do any tricks you can to make your car faster.there is nothing wrong with a winning legal car.do remember parents its about children. After setting your axles (nails) careful turn car upside down put a little glue on the end of the pointed part of the nails. Seen them come off on race day not a good think to happen

how do i make a derby car go faster any ideas thanks!

make the car as heavy as possible

My son and I had great experiences building his cars together; he doing the labor and me in a supervisory role. In addition to the tips already listed, don’t forget that a good, smooth paint job can make a difference too. Light sanding between coats and finishing with a clear coat will help your speed and ensure you car looks good on the shelf in your room for years to come. Have fun!

i got first in the pack thanks to this

just won

what should i use to enhance my wheels?

In the BSA kit the axles(nails) have ridges in them, is it okay to sand them off?

cool tricks they realy work

In our Pack we do not allow three wheels on the track – it is a 4 wheel event. We also allow the polishing of the nails (axles) and you should definitely remove the burrs on the heads – this is what slows the car down right out of the box.

you want your car to work correctly, than yes you should

if you want a fast car, you should

does trail to eagle cover first class

yes

There are all kinds of web sites that tell you how to file, sand & polish the axels but we were told by Pack Leader and race officials absolutely not. We were to remove parts from box and to use as is to ensure even and fair races.

yes it is ok

NO if you sand your axels it can go in in even and slow your car down you should probably just get a new set of Axel’s they sell them as far as I know of at micheals and BSA stores

Yes, sand/file off the ridges. Use a triangle file to round or bevel the hub as to not rub on the wheel. The axle should be wet sanded starting with at least 300 and progress up to 2000 wet sand. The shinier the better.

Be sure to check your District’s rules before assuming these modifications are permitted. In our district, we must use only the materials in the derby kit (i.e., no precut cars from the hobby shop, non-BSA wheels and axels, liquid lubricant, etc.). Further, changing the wheelbase in many districts is a big no-no.

Terrific book!! I like the fact that the author keeps telling you to check your local pack rules. My son has about worn this book out!!! Great book! Thanks for helping many boys dreams come true.

Another speed tip: Use the power/cordless drill to polish off those burrs in the axle (nails) to gain more speed. Insert the nail tip in the power drill, tear off a 1/4″-1/2″ strip of 150 grit sandpaper, wrap it around the nail and polish that burr off first. Then use 320-400 grit after that, then work your way up. I go as far as 1000-1500 wet/dry paper to get is super smooth. Less friction=SPEED 🙂

use the flakes of graphite and spin your weals

I am helping my son build his first derby car. The race is Jan. 28th. I have a question. The wood block comes with the axle slots in it already. Do you just hammer in the axles and they stay in the slots without popping off the bottom? Seems like they would come off the car a lot… Any advice would be great!

Correct, it will not go out the bottom of the slot. Also, don’t use a hammer because you could bend the nail. Line it up well and push it right in with your finger or with another small piece of wood…Press fit

Ok, thanks. We are baking the block today and are going to band saw out the car design. I will make sure we do not hammer the axles in.

it depends the way you want it.But I think maybe if you pound them in, it would keep the wheels on better. But I can’t guarantee the car will go fast.

Good luck!

Sometimes it helps to put a wheelguard over the axles. You could put a dab of glue near the axles just in case. Do NOT get glue on the wheels. I have a friend that put glue on his axles, and overnight the glue seeped onto one of the wheels. !t didn’t spin at all. Be careful and have fun!

You can leave them just hammered in, but Ive been racing a wile and i recamend you super glue the bottom.

glue them!

Boys life is great!!

what is the scientific reason to make it the heaviest so its the fastest

Larger mass means larger momentum. The larger the momentum, the longer it takes the frictional force to reduce the speed to 0.

About half the tips in this article are illegal in our derby and would not past inspection. Glue on the axel, 3 wheels touching, Extending the wheel base are all against the rules, so make sure you know your rules before doing any of these tips.

Good point!!! In our pack it is legal to have three wheels touching and an extended wheel base. However; when in doubt check with your individual pack, district rules.

Can anyone tell me the purpose of baking the block and making it lighter?

Drying the wood eliminates extra weight from the block of wood. The only weight you want to add to the car is some type of metal. There are different densities from different materials you can use. The idea is to have all your weight as low as possible, (center of gravity). It gets pretty scientific after that. Only doing 1 little thing wont make much difference in the speed of the car. But, if you do 10 little things, that is the difference maker. Good Luck!

Nice tip on the “10 little things” – we’re talking mini-seconds with each “little thing” but they do add up..

The purpose is to extract as much moisture as you can from the wood. Moisture is weight, and since you will be adding weight with painting, why not cancel some of that weight by eliminating water that serves no purpose from the wood.

To avoid warping the block from the oven drying process (or risking the possibility), do you think drilling holes in the body to take out weight will do the same thing? If holes are OK, where are the best areas to drill?

Supposedly to make the block lighter to add more non wood weight. The problem with baking the block is that it will more than likely cause the block to shrink a little amd warp. This will leave you with a block that is not square!! The block would have to be vertically grained to minimize this. Most blocks are slab grained with the grain not running at 90 degree angles from top to bottom.Don’t bake the block!!!

To add to this, if you bake Revell brand blocks that are made in China, sap will begin to ooze out. Yep, they aren’t using kiln dried wood so you wind up with a block that is useless because your car will weigh more on one side or the other.

Here is the real secret: Let the boy make the car with your help. Don’t do it for him. Teach him that all ideas are valid. As adults we want to win, as youth, they just want to have fun. Enjoy your derby even if you don’t use all these speed secrets.

Agreed!!!!!

True… But its disheartening when your 5yr old can’t even place or have a chance against a car build by a father who is an engineer…

I was the youngest scout to make it to the finals and I’m confident that with this help I’ll get 1st place for sure!;)

oops, typo alert “youngest scout LAST YEAR to make it to the finals”.

Our pack is FULL of people that say ‘I don’t like that’ or ‘that’s not fair’ What is fair is that you follow your rules and spend time with your boys making and creating the car. My boys design the car, paint the car and I help it GO (faster) I use as many tips as i can get and pass it on to them so they will do them later

Derby rules for us is to use BSA derby axels.

I love this! I will try it!

For Pinewood purposes, the nails in your kit are called “axles.” Most packs cannot use real “axels” on thier cars. But those look COMPLETELY different than nails.

Remember, do your best on your wheels and axles, but it is the wheel alignemnt that wins the race. The Scout stores have some great tools for building a great car and getting a good alignment.

I agree about wheel alignment also proper weight placement. My son who placed first overall in his pack and district events two years in a row spent a lot of time with his alignment and weightt placement. The average time for his car in 2011 on a 42′ aluminum best track were 2.9500 seconds. His best time was 2.9014! Weight placement and alignment are the best tips for any body. It was a shame that he was too ill to race in our region race. Nice chatting with you.

what about the wheels?

I don’t like the idea about raising one wheel to cause less friction…that doesn’t sound fair. Not to mention it is a four wheel vehicle….no where does it say you can use 3 wheels that I have seen.

It’s a simple trick and doesn’t cost a dime. You still have four wheels on the car. Unless your rules prohibit it, you’ll probably end up with at least half the cars with 3 wheels touching the track just by sheer accident. You’d be suprised how many cars show up with a raised wheel without it intentionally being built that way. It is “do your best”…..right?

I don’t like the idea about raising one wheel to cause less friction…that doesn’t fair. Not to mention it is a four wheel vehicle….no where does it say you can use 3 wheels that I have seen.

none of the rules say you can’t

Before you build, ask. Nothing sucks the life out of a scout or the derby committee more than a car that does not meet the event specifications. While all of those ideas sound GREAT, and they probably work, some of them would violate the rules of your pack. district/ council derby.

so this is still for the boys right?? I mean most 7-13 yo boys can do this alone. Just make sure after you build it give HIM credit so he gets his awards.

imade graphite ports as the car moves down the track it puts more onthe wheels.

really? did it work? how did you do it?

2first places!

cool info

Im trying it right now!

I think this is real is cool because of the ideas

Reuse your already polished axles.

I reccomand using nails instead of axles. We had a practice race 1 week ago and the people who use nails are more likely to win. I used axles but I lost. Hope I helped. Peace out :))

Our Pack 131 isnt allowed to use axles.

That is weird we are aloud

same here, no axles

I am at the wheel installation stage. I’m concerned that the wheels will slide from the outer end of the axle and scrape the body. Is there anything I can do to keep them in place?

This is tricky. Some people advocate angling the nails or axles in the rear slots one degree backward to supposedly help prevent the wheels from making contact with the body. I think this would actually slow the car down because you would have the wheels working against each other when the car rolls down the track. The best and safest way to minimize wheel contact is proper wheel alighnment. Also, pack graphite on the car’s body where the wheels make contact. Washers are not acceptible.